When you hear Trace to Origin, we’re actually referring back to Lot Tracking. Lot Tracking is important in many industries but specifically the food and beverage industry. The US Food and Drug Administration (FDA) is responsible for the safety of food products sold or manufactured in the United States. Any product that requires FDA approval is mandated to use a lot tracking system, which means that during an audit or a recall you must be able to provide them with the information as to where you purchased the product, what you did with it (production) and who you sold or gave a sample to.

While the FDA is an important enforcer, your customer is probably even more so. The lot tracking requirements laid out by larger retailers are more stringent than the FDA, and often require you to perform mock recalls to prove you have your processes sorted out.

What is Lot Tracking?

Let’s start at the beginning: A lot is one particular batch of a product manufactured at one time. The lot is then usually assigned a specific number or code which gives the ability to track manufactured lots/batches and the entire supply chain from supplier and distributor, to the customer.

Lot tracking is a system used to trace ingredients associated with a group of products back to a manufacturer or supplier, and it is also used to organize inventory by production or expiration date. Most food safety emergencies result from errors in processing, but an efficient lot tracking system will help mitigate the situation quickly and with minimal damage, if not preventing it from happening altogether.

Proper lot tracking can also limit the scope of recall as most organizations ‘go wide’ as a risk mitigation strategy. Using a pen and paper or spreadsheets approach was fine when for a fledgling business, but as the business grows, so do the associated problems with a manual process, the most significant being those of time, and the many disastrous scenarios that can occur due to a small mistake.

Why is Lot tracking important?

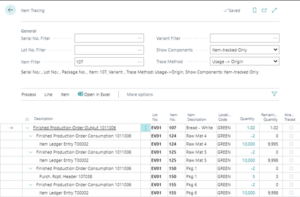

There are many reasons to have a reliable lot tracking system, but perhaps most important is in the case of a food recall activity. Without knowing where your products have been or have gone, you won’t be able to identify who may have come into contact with them, or what else may be at risk of contamination.

In case of a recall, you know where the product came from, where it’s stored, and where it ended up. This allows you to trace and acquire the product back if needed.

Benefits of Lot tracking

The ultimate goal and benefit of lot tracking is a 360° view of everything related to your product. The other benefits include:

Vendor performance

To do business with the biggest customers, you need to have a lot tracking process in place. You need to be able to respond in a short window of time and provide confidence in your data.

It also provides you with an overview of the full supply chain in real-time. This helps your business stay organized and have traceability on all products.

Limit human error

Improve your business operations with automated data which helps minimize human errors. Humans aren’t perfect, and with a large capacity of data, just one mistake can lead to a domino effect of improper information. An advanced lot tracking system reduces the need to manually create/keep track of data and ensures accurate information is available when needed.

Organization

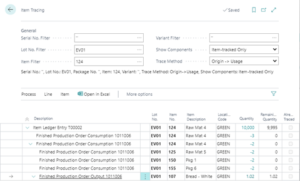

With an efficient tracking system in place, you are able to print standardized and consistent bar codes for your products – saving both time and money in your production process. Manage inventory control in real-time, configure your warehouses as needed, and accurately track lots through the entire manufacturing process, and stay on top of any changes in FDA regulations.

Efficiency

Expediting the tracking process is vital when it comes down to a health and safety issue or a retailer’s mock recall program. Automated lot tracking will make what is a very complicated process smooth and identify the issue in minutes, rather than hours and days, eliminating the need to put all lots of a product on hold. In addition, the lot tracking tools can also generate recall letters for suppliers and customers.

Manage expiry dates

Another reason why it is important is when it comes to food expiration dates. This is referring to the FEFO (first expiry, first-out) system. The FEFO system helps perishable food businesses send out the batch they received first so that it doesn’t expire. If you need to know which batch you received first, lot tracking helps you by keeping a record of the full supply chain.

Brand management

The ultimate goal of lot tracking is to ensure the safety of your customers, and consequently that of your brand. Should a contaminated ingredient not be identified and tracked in time, that means more items need to be pulled off the shelves, and buyers start to have negative associations with the overall brand, thus decreasing the volume sold. So not only is efficient lot tracking saving money in the process but is minimizing the impact on your future profits as well.

How much of my warehouse processes can I automate?

All of them! But you need to implement the processes that work best for your business. Here are the different levels of automation possible:

Conclusion

All of the reasons above come down to the important fact that lot tracking will help you save money. Allocating costs for recalls, keeping track of your inventory, and serving your customer with quality food will help you stay on track with your business goals.

Lot tracking is essential to the perishable food industry. Harvest Food Solutions can help you integrate it into your business. We specialize in software specifically for the Food and Bev industry and will provide you with our software that will optimize your business.