Harvest Food Solutions has been awarded the Innovation Showcase award for the upcoming International Baking Industry Exposition (IBIE) — the grain-based food industry’s largest, most comprehensive event. Harvest has won this award for the second time – the first being at IBIE 2019 for Harvest DSD.

The award was presented for Harvest Advanced Manufacturing for Bakeries, identifying it as a state-of-the-art innovation. Companies in the Innovation Showcase are those recognized for their work toward bettering the baking industry.

Award winning software for bakeries

Harvest Advanced Manufacturing for Bakeries simplifies the complex requirements of manufacturing baked goods products. It helps in creating production schedules, grouping like items, managing unique baked goods changeover requirements, all while tracking granular costs throughout the multi-site/multi-line manufacturing and wrapping processes.

For far too long in the baking industry, the availability of innovative, comprehensive operations software has been significantly outpaced by de-centralized machinery improvements. In fairness, functional machinery has provided an ROI in tangible ways, whereas software has been seen as “a nice to have”. That time has come to an end.

Innovative software doesn’t just start with a flashy home screen. Rather it is the ability to simplify the complex requirements of manufacturing baking products. It is the development of time-saving and informative process improvements. It is the design of user-centric production schedules, grouping like items, and managing unique food changeover requirements, all while tracking granular costs throughout the multi-site/multi-line manufacturing and wrapping processes.

Innovative systems enable companies to make decisions and feel supported throughout their entire operation. Having the right pieces in place reduces training requirements, reduces errors, and improves real-life functional performance.

Innovative features

Harvest Advanced Manufacturing for Bakeries offers the following innovations to meet the needs of today’s modern baker:

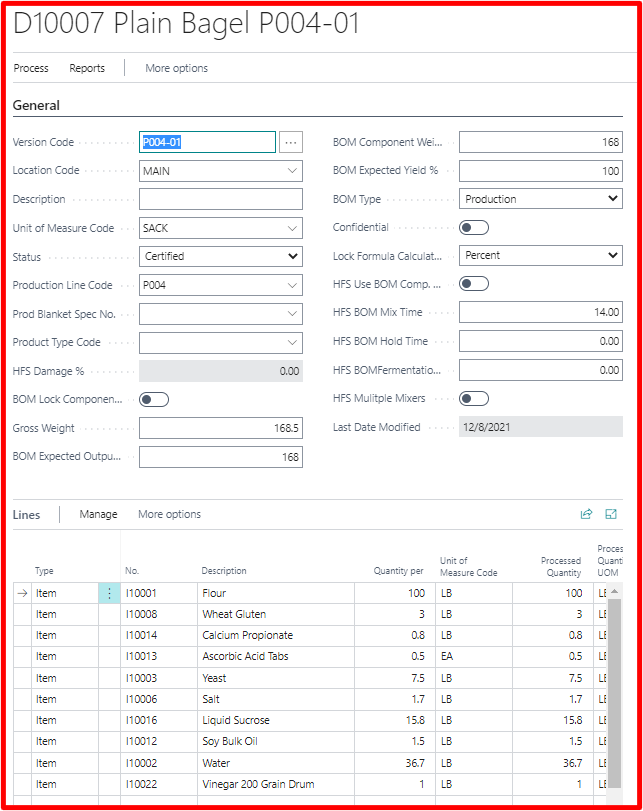

Build of Material Enhancements:

- RECIPE Versioning by Location

Allows to control production consumption and costing at each manufacturing location(s) and production line(s). - Pan Type

Manage unique pan types in the system to track configuration size and reglazing estimations. - Product Types

Allows the system to group similar finished good products together to drive the basis of scheduling and the creation of production orders to drive material needs. Product Types are assigned to the completed Item and retains the master data that captures the process requirements during creation.

Production Scheduling Designs:

- Batch Scheduling

Allow scheduling of production by Bill of Materials batch size or by a baking industry-standard of scheduling by Sack size. - Dynamic Rescheduling

Once the schedule has been published and something happens like a production line breakdown, the schedule may be recalculated from point of breakdown. - Production Schedule Breaks

Configurable break codes (i.e. change over, engineering, shift) to capture scheduled downtime in the production schedule. - Production/Shipping Multi-Day

Consolidate multiple days into a specific production day. Consolidates multiple days of orders into a particular day to be shipped or can factor in additional lead time for transportation back into production to meet the demand requirements. - Shift Demand

Move bulk order demand between production location(s) to feed and change the production schedule.

Costing Enrichments

- Blanket Specs

Provides function for capturing costing and overhead components that can be deployed to production bill of materials for individual or like grouped items. - Change Over Between Product Types

Change over time required between products for allergens, a different type item, cleanup, etc. is calculated automatically. Once the schedule is generated, a break time may be manually changed or add a one-time break that does not affect the master Product Type setup. - Production Sequencing

A default setting that determines which finished good products are produced. Once the production schedule is created, production may override the sequence order of when products are produced while still respecting product type change overs. - Create Production Orders from Scheduling Tools

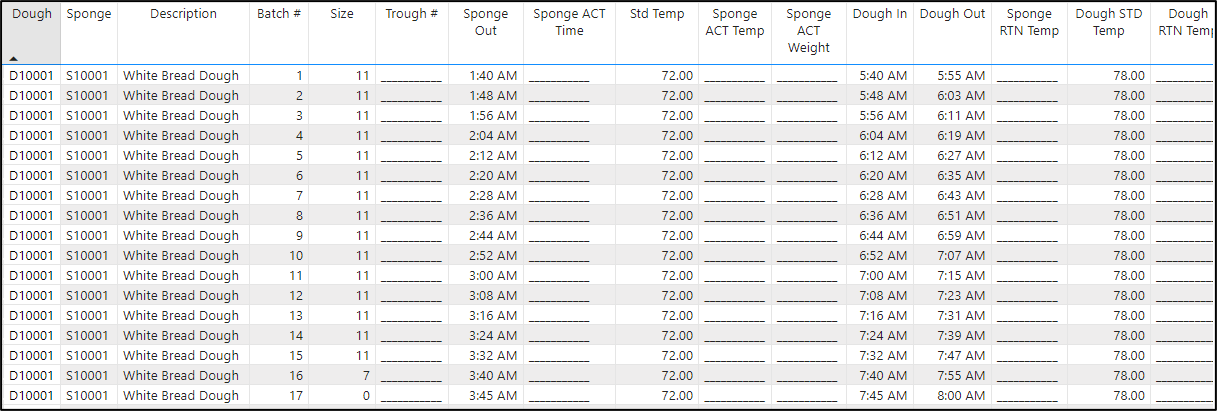

Create production orders directly from the production schedule and production sequencing screens to be used for MRP and consumption. - WIP Production Schedule

Generate a WIP/Mixer Schedule from the Production Sequencing. View and manage the WIP production schedule and evaluate capacity and batches scheduled. - Production Order Quick Entry

Simplifies the production order entry process and allows to quickly key and complete consumption process for production orders. - Dynamic Weekday Item

Used to set a master item that will be placed on a bill of materials but will consume specific items based on a given day of the week as indicated by the dynamic weekday item setup. (i.e. kwik loks).

See it for yourself at IBIE

The IBIE 2022 Expo is taking place Sept. 18-21, 2022 at the Las Vegas Convention Center. Harvest Food Solutions will be located at Booth #957, where we will also be demonstrating products Harvest Advanced Manufacturing for Bakeries.

Visit BakingExpo.com to register and use the code EXH957 to get 20% off your registration.

Will we see you in Vegas?